Novinky EN (14)

30 Years of Innovation, Growth & Sustainability! 🎉

The end of the year 2025 was a milestone for PEBAL s.r.o. – we celebrated 30 years in the market! 🚀

Since our humble beginnings in 1995, we have become a trusted partner in the packaging industry. Thanks to continuous investment in technology, quality, and sustainability, we now deliver innovative solutions to a wide range of industries.

🛠 Quality & Innovation – We continuously expand our product portfolio and implement cutting-edge manufacturing technologies.

🌱 Sustainable Production – Our 1 MWp solar power plant saves more than 320 tons of CO₂ annually.

🤝 Long-term Partnerships – Our growth and success wouldn’t be possible without the trust of our customers, business partners, and amazing team.

This anniversary is not just a milestone, but a commitment to the future – to keep improving and innovating so we can become even stronger together.

Thank you for being part of our journey. We look forward to many more years of success together! 💙

🎥 Looking Back at an Inspiring 2024! 🌱

The new year is the perfect opportunity to reflect on the remarkable moments of the past – and one of them is our video created especially for the Readycon2024 platform. This initiative connects high school students with opportunities for their future careers, and we’re proud to have been part of it. 💼✨

The video features our colleagues Barbara Svobodová and Václav Zedník, who shared their inspiring professional journeys. Václav talks about his path from his first steps at PEBAL to becoming a key member of the production team, while Barbara highlights how her dedication and hard work led her from a junior position to a managerial role.

The video not only presents career growth opportunities but also emphasizes the importance of sustainable practices and modern technologies that are at the core of what we do.

2024 brought us plenty of inspiration – and we’re excited to see what the new year has in store! 🚀

Curious about the opportunities we offer to young talent? Watch the video or get in touch with us. 📩

Media

🌱 We’re Excited to Announce: PEBAL s.r.o. receives the PRS Green Label 2024! 🌱

We are proud to be recognized for our commitment to sustainability with the PRS Green Label! 🎉

✅ We returned 1,815 pallets ♻️

✅ Achieved a recovery rate of over 65%

✅ Saved 259 trees 🌳

✅ Our best month: March 2024

We’re committed to driving a circular economy and making the world a greener place! 🌍💚

🌟 We celebrate our incredible PEBAL team members who have dedicated more than 15 years to the journey together! Your unwavering commitment and expertise have helped shape our success and inspire everyone else.

Thank you for embodying the values that define us, and we look forward to many more years of cooperation and joint success! 🚀🎉

Media

🎓 PEBAL Dobřany – visit of students from UTB Zlín

During WK11 we had the opportunity to welcome a very pleasant visit from students of the 2nd-4th year of the Polymer Engineering field from the Univerzita Tomáše Bati ve Zlíně.

It was our pleasure to introduce the students to the operation of the company incl. tours of production facilities. Part of the extrusion lines was taken care of by our colleague Tomáš Matějíček, who is our technologist and also a graduate of TBU in Zlín.

👋 We believe that the excursion into the modern world of the plastics industry was beneficial and we look forward to further visits!

Media

Our operations in Dobřany would not be complete without laboratory facility that help us meet the various required properties of our products. Across customer requirements it is necessary to always achieve the highest possible standard.

Every day, our experienced colleagues test physical-mechanical properties such as:

- Strength & ductility

- Slippery

- Stickiness

- Antistatic

- Ionization - surface tension

- And more…

Let's take a brief look at what one of the tests we do looks like.

Media

PEBAL GROUP a.s. with headquarters in Dobřany in the Czech Republic, announces the acquisition of a majority ownership stake in the Czech manufacturing company MILCOM MILPACK s.r.o.

MILCOM MILPACK s.r.o., based in Dvůr Králové nad Labem, continues the tradition of operating the MILCOM a.s. production plant, where the beginnings of activities related to packaging machines date back to the mid-1980s. Until 2002, the company mainly produced spare parts and repairs of dairy machines. Since 2002, the company has renewed the production of new machines, mainly focusing on the packaging of butter and quark. Due to many years of experience and innovations in the packaging of paste-like products, the main activity of the company has been transformed into the production of bags (stand-up pouches), for which MILCOM MILPACK is now recognized as bag-maker including the former core area of machines production.

MILCOM MILPACK s.r.o., based in Dvůr Králové nad Labem, continues the tradition of operating the MILCOM a.s. production plant, where the beginnings of activities related to packaging machines date back to the mid-1980s. Until 2002, the company mainly produced spare parts and repairs of dairy machines. Since 2002, the company has renewed the production of new machines, mainly focusing on the packaging of butter and quark. Due to many years of experience and innovations in the packaging of paste-like products, the main activity of the company has been transformed into the production of bags (stand-up pouches), for which MILCOM MILPACK is now recognized as bag-maker including the former core area of machines production.

PEBAL GROUP a.s. is 100% Czech owned family company, with four production plants in CZ & SK. PEBAL GROUP a.s. specializes on the extrusion of PE films and the production of flexible packaging for various industries (food, hygiene, construction, agriculture). PEBAL GROUP a.s. offers a wide range of sustainable packaging solutions such as recyclable packaging, packaging with recycled content, biodegradable packaging and bag-making of stand-up pouches, supporting the unique flexo printing technology with EGP (Expanded Gamut Printing). Other engineering activities include production and service for the dairy sector.

We welcome colleagues from MILCOM MILPACK s.r.o. in our PEBAL family and we are looking forward to working together.

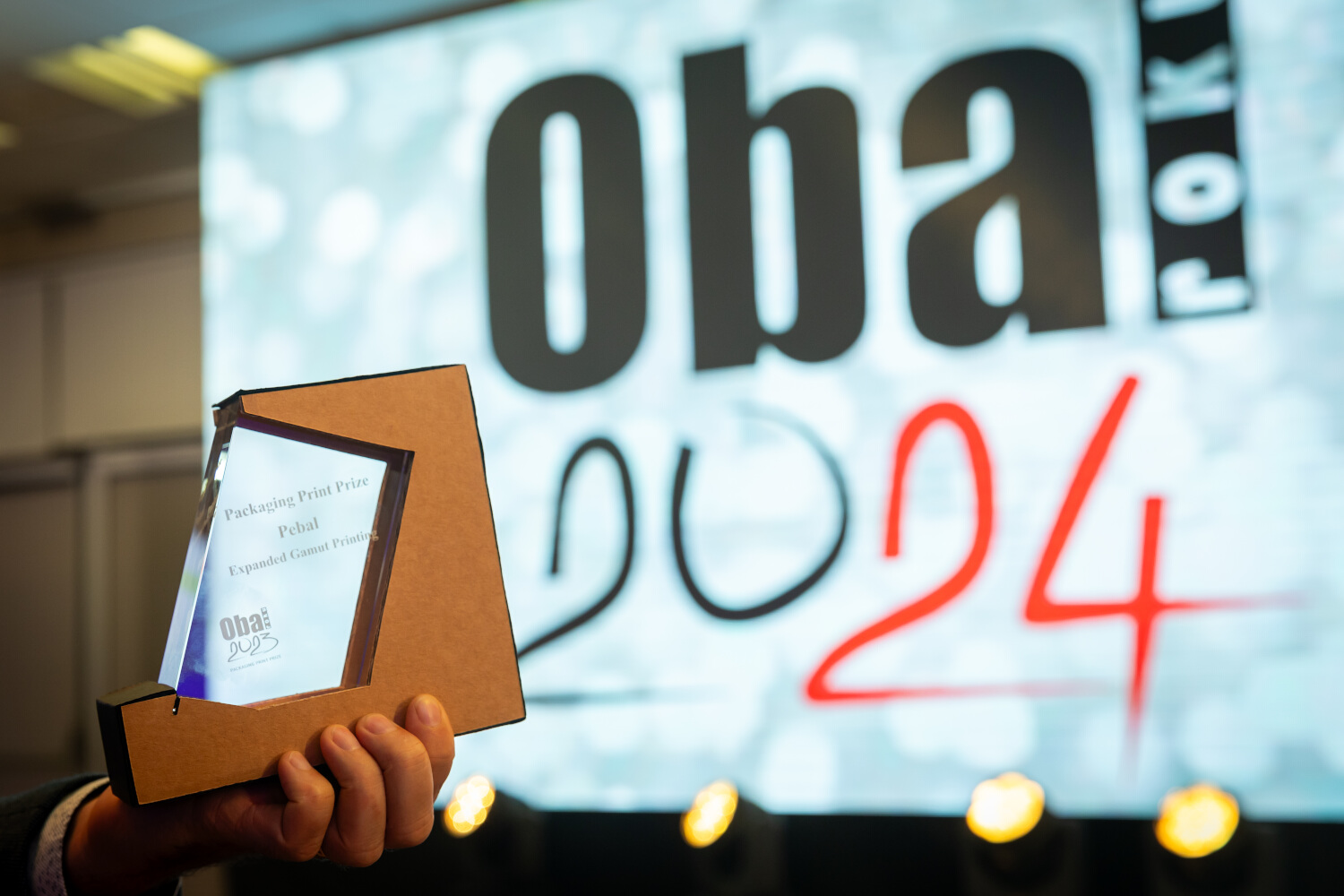

Last month, during the awards evening of the OBAL ROKU 2023 competition, we officially received the award in the process & technology category.

With great enthusiasm, we also accepted the special Packaging Print Prize for exceptional quality / innovation in packaging printing under the patronage of the Společnost tisku z.s.

We really appreciate that the long-term development of our printing department has been beautifully recognized in this way, and it is mainly thanks to the long-term and hard work of our employees that we have achieved such success.

We thank our customers for their cooperation and trust, which motivates us to push our innovations further!

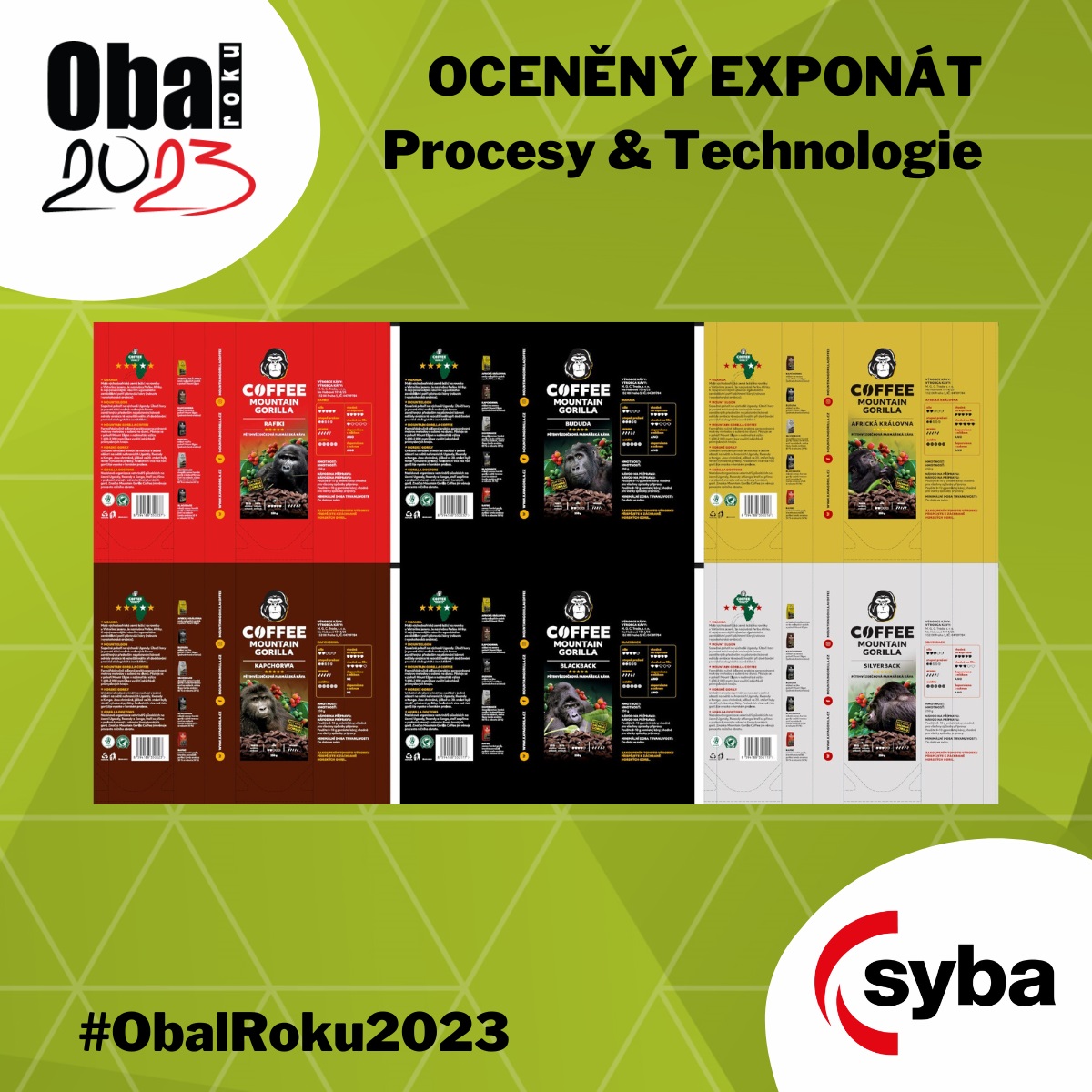

As part of the 30th year of the OBAL ROKU competition, we won an award in the process & technology category!

Our solution for Multi-Layer Coffee Barrier Packaging combines 6 different motifs in a single printing job!

The author of the structure of product is Václav Zedník.

Thanks to the flexo printing method using EGP (Expanded Gamut Printing), this solution offers an excellent alternative to rotogravure and traditional spot color flexo printing.

Using this technique, we achieve high-quality printing using CMYK process colors with OGV (orange, green and violet) additive colors.

This advanced printing method reduces dependence on Pantone shades up to 90%, which leads to lower consumption of materials (paints, thinners and printed materials), energy consumption and CO2 emissions incl. optimization of color management.

We thank our colleagues for their great work and our partners and customers for their trust and cooperation.

Our company has taken another important step towards sustainability by implementing a modern solar panel system at its production plant in Dobřany. This step is proof of the company's commitment to environmentally responsible practices. By using solar energy, Pebal takes a proactive role in reducing its dependence on traditional energy sources with an estimated self-sufficiency rate of approx. 17.5%.

- Installed power 1MWp

- A total of 2,172 solar panels

- Area approx. 6,000 m2

- CO2 savings of more than 320t per year

In today's rapidly evolving world, sustainability has become an urgent issue. The plastics industry in particular way is under scrutiny for its impact on the environment. However, our industry has made significant progress in adopting greener practices through the use of PIR and PCR materials. In this post, we will learn about the importance and benefits of these materials and shed light on their potential.

PIR: Post-industrial recycled materials are plastic waste generated during the manufacturing process. This is not direct disposal, but the material is recycled and reused to create new products. This innovative approach not only reduces the amount of plastic waste ending up in landfills or the oceans, but also minimizes the need to produce new plastics. By using PIR materials, the plastics industry can significantly reduce its carbon footprint while promoting a circular economy.

PCR or using the potential of consumer recycled materials, on the other hand, in our case, are plastics obtained from products that have completed their life cycle as consumer goods. These materials are regenerated, sorted and cleaned before they go through the actual recycling process. PCR materials provide an excellent opportunity for the plastics industry to minimize its dependence on original input materials. By collecting and reusing plastic waste from consumers, the plastics segment of the industry can make a significant contribution to a more sustainable future.

Education plays an absolutely essential role in promoting a culture of sustainability. Raising awareness of the benefits of using PIR and PCR materials can inspire individuals and businesses to make greener choices. By understanding the positive impact of their decisions, consumers can actively seek out products made from recycled materials, increasing demand and encouraging manufacturers to adopt sustainable production practices.

Even we at Pebal understand that the adoption of PIR and PCR materials is an important step towards creating a more sustainable plastics industry. Therefore, the current representation of these materials in our production is approximately 18% of our total production. By reducing waste, conserving resources and minimizing environmental impact, these materials offer a transformative solution. Let's embrace sustainability together and reshape the plastics industry for a better tomorrow.

We are fully operational after summer technological shutdown when complete maintenance of our machine portfolio took place at our Pebal plant in Dobřany.

Watch a video of our extrusion lines ready for production demand through the rest of 2023.

Media

Our company PEBAL took part in the INTERPACK trade fair in Düsseldorf .

Pebal Group, headquarted in Dobrany, Czech Republic, aquires 100% of shares of the Slovak packaging company Fol-Kontakt.

Fol-Kontakt, headquarted in Zilina, Slovakia, was founded in 2003 and is a company specializing in PE film extrusion, printing and bag-making. Company’s main focus is on specialty films, mainly for the industrial packaging. Fol-Kontakt offers for its customers sustainable solutions.

Pebal Group, is a 100% Czech owned family company, with 3 manufacturaing sites, in 2 countries. Pebal Group focuses on PE film extrusion and packaging for different industries (food, hygiene, construction, agriculture). Pebal Group offers a wide range of sustainable packaging solutions as recyclable packaging, packaging with recycled content and biodegradable packaging, backed with a unique Flexo Expanded Gamut Printing Technology.

A warm welcome to our colleagues from Fol-Kontakt to our Pebal Family and we are looking forward to our cooperation.