News

-

more...

Summer production shutdown 2025

Dear business partners,

We would like to inform you, that all production centres of Pebal will be shutdown from 30th June 2025 to 13th July 2025 due to the planned technological shutdown.

The restart of the production will take place on Monday, 14th July 2025.Dispatch, warehouse, sales and customer departments will normally operate even during the production shutdown.

-

more...

PEBAL 2025

30 Years of Innovation, Growth & Sustainability! 🎉

The year 2025 is a milestone for PEBAL s.r.o. – we are celebrating 30 years in the market! 🚀

Since our humble beginnings in 1995, we have become a trusted partner in the packaging industry. Thanks to continuous investment in technology, quality, and sustainability, we now deliver innovative solutions to a wide range of industries.

🛠 Quality & Innovation – We continuously expand our product portfolio and implement cutting-edge manufacturing technologies.

🌱 Sustainable Production – Our 1 MWp solar power plant saves more than 320 tons of CO₂ annually.

🤝 Long-term Partnerships – Our growth and success wouldn’t be possible without the trust of our customers, business partners, and amazing team.This anniversary is not just a milestone, but a commitment to the future – to keep improving and innovating so we can become even stronger together.

Thank you for being part of our journey. We look forward to many more years of success together! 💙

-

more...

Readycon 2024

🎥 Looking Back at an Inspiring 2024! 🌱

The new year is the perfect opportunity to reflect on the remarkable moments of the past – and one of them is our video created especially for the Readycon2024 platform. This initiative connects high school students with opportunities for their future careers, and we’re proud to have been part of it. 💼✨

The video features our colleagues Barbara Svobodová and Václav Zedník, who shared their inspiring professional journeys. Václav talks about his path from his first steps at PEBAL to becoming a key member of the production team, while Barbara highlights how her dedication and hard work led her from a junior position to a managerial role.

The video not only presents career growth opportunities but also emphasizes the importance of sustainable practices and modern technologies that are at the core of what we do.

2024 brought us plenty of inspiration – and we’re excited to see what the new year has in store! 🚀

Curious about the opportunities we offer to young talent? Watch the video or get in touch with us. 📩

-

more...

PRS Green label 2024

🌱 We’re Excited to Announce: PEBAL s.r.o. receives the PRS Green Label 2024! 🌱

We are proud to be recognized for our commitment to sustainability with the PRS Green Label! 🎉

✅ We returned 1,815 pallets ♻️

✅ Achieved a recovery rate of over 65%

✅ Saved 259 trees 🌳

✅ Our best month: March 2024

We’re committed to driving a circular economy and making the world a greener place! 🌍💚

-

more...

Fachpack 2024

🌟 Exciting News from PEBAL GROUP! 🌟

We are thrilled to announce our participation in FACHPACK 2024, one of the premier packaging exhibitions in Europe! Join us in Nuremberg from September 24-26 as we showcase our latest innovations and cutting-edge solutions in the packaging industry.

📍 Find us at Hall 5, Stand 5-226!

Don’t miss out on this opportunity to meet our team and discover how PEBAL can help elevate your packaging solutions to the next level. We look forward to seeing you there!

-

more...

PEBAL - club 15+

🌟 We celebrate our incredible PEBAL team members who have dedicated more than 15 years to the journey together! Your unwavering commitment and expertise have helped shape our success and inspire everyone else.

Thank you for embodying the values that define us, and we look forward to many more years of cooperation and joint success! 🚀🎉

About us

-

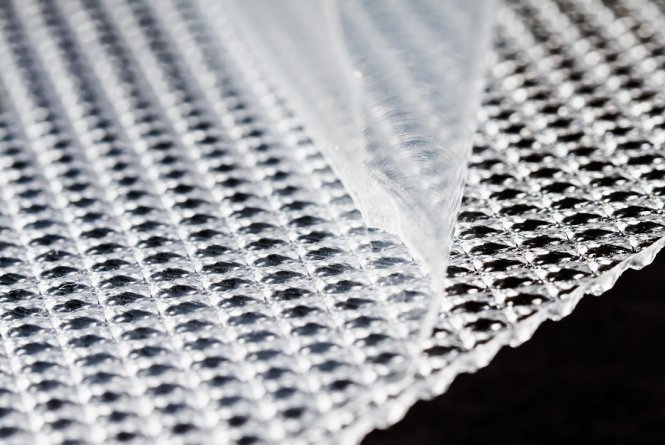

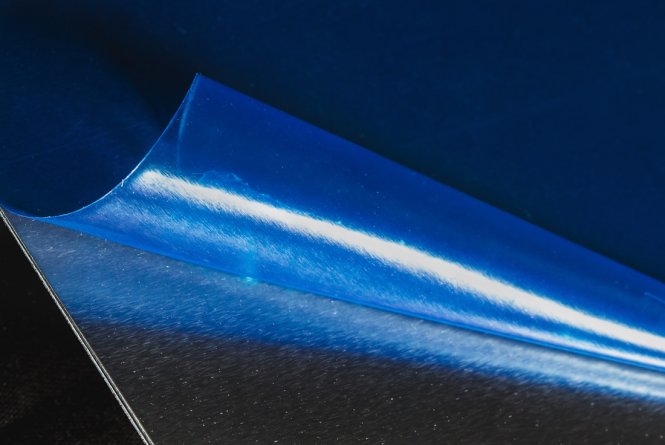

PEBAL s. r. o. was founded in 1995, as a trade company. Nowadays, Pebal is one of the largest manufacturers and suppliers of packaging materials in Czech Republic. At the end of 2018, the company moved to new premises near Pilsen (Dobřany), where 50,000 m2 of modern production and storage area of the company is located.

We cooperate

Contacts

-

PEBAL s.r.o.

Vysoká 1297, 33441 Dobřany

Phone.: +420 377 882 811

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

VAT: CZ64830942

Map

Contact us